Film Tech LLC Capabilities

.jpg)

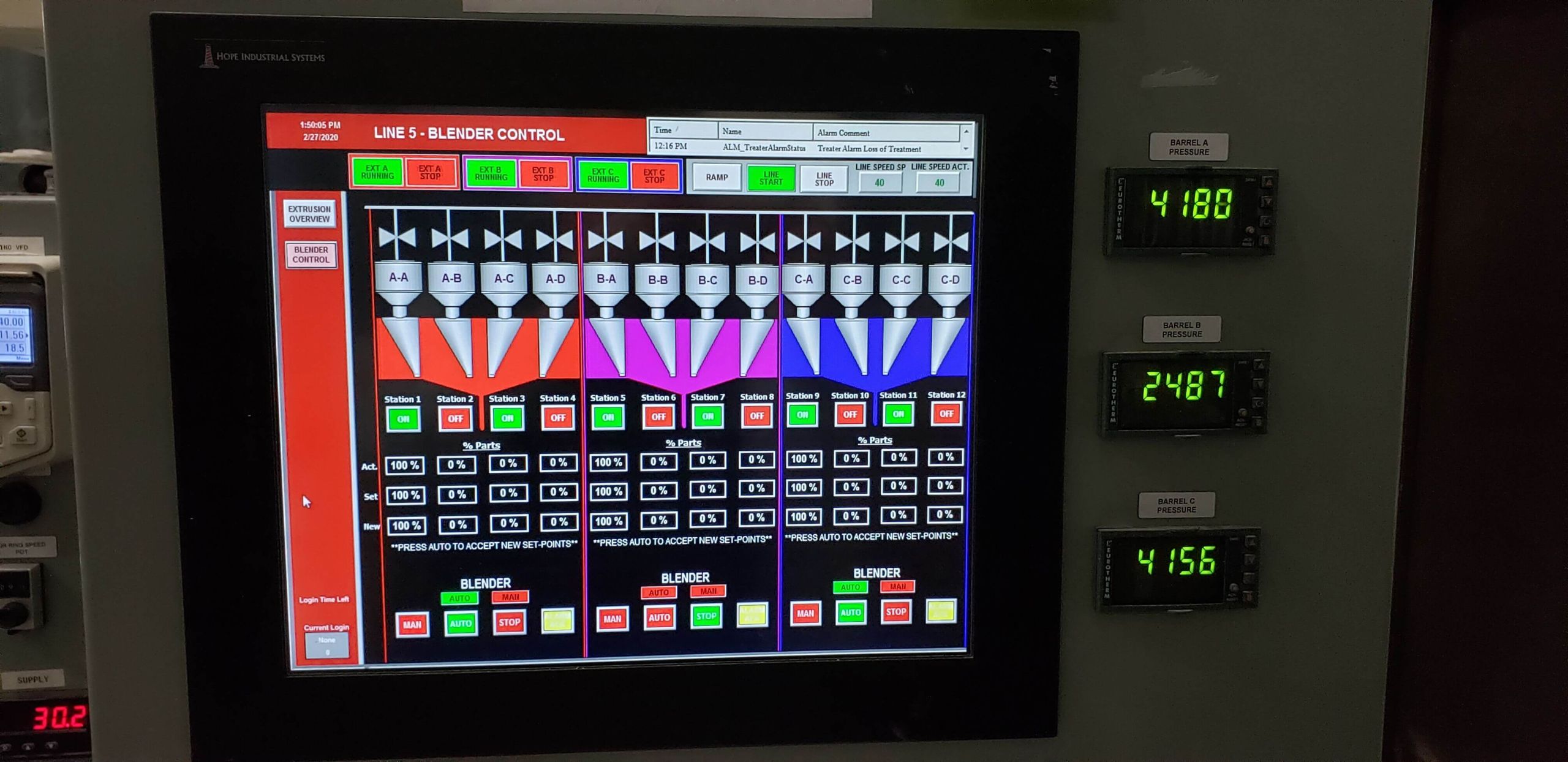

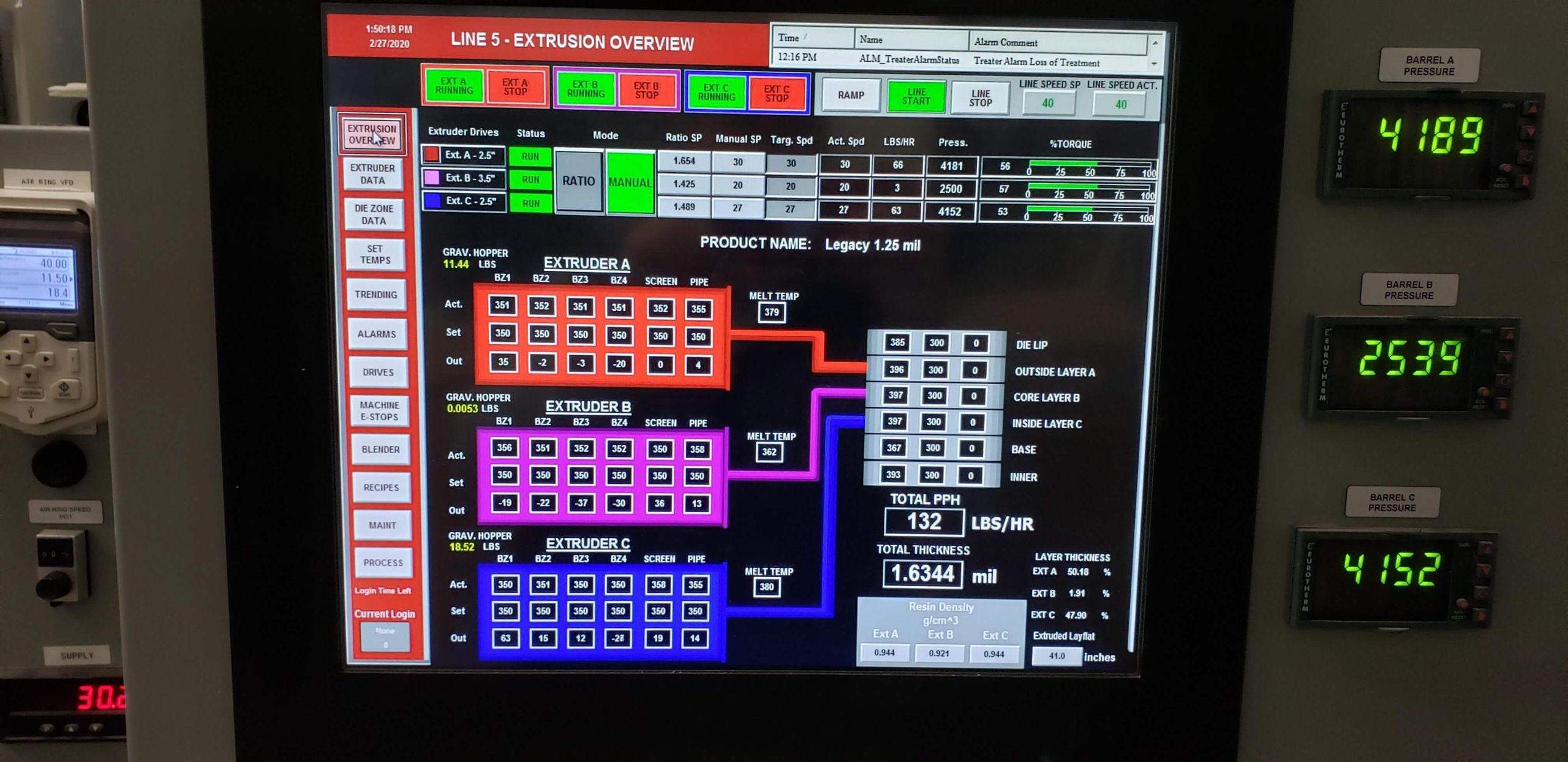

Film Tech LLC offers COEX and MONO-layer blown films. Our film products are based on proven technology that allows for performance attributes to be customized to meet the end use requirements. Pellets of resin are melted and literally blown through a mechanism that allows the molten resin to flow and form a tube called a bubble.

Speed to market demonstrated over three decades!

- COEX 3-layer

- Monolayer

Monolayer films are a single layer that can be composed of many components evenly distributed throughout the film sheet.

COEX films are extruded films of 2 or more different thermoplastic resins in a sandwich-like film.

.jpg)

- Polyethylene (uLDPE, LDPE, MDPE, LLDPE, HDPE, mLLDPE), metallocene

- Polypropylene

- EVA

- EMA

- Surlyn

- COC

- POP (Polyolefin Plastomer)

- POE (Polyolefin Elastomer)

- Compostable Resins (PLA,PBS,PBAT,Others)

- Renewable Polyethylene

Custom toll programs for proprietary blends. Contact us to learn more.

- Slip

- Color

- Anti-block

- Anti-stat

- Antimicrobial

- Fire retardant

- Oxo-biodegradable (OBP)

- Soft touch

- Paper feel

- UV inhibitor & blockers

- Security tracers

- Fillers

- Decorative additives

- Post consumer/industrial

- UV brightener

- Slip

- Color

- Anti-block

- Anti-stat

- Antimicrobial

- Fire retardant

- Oxo-biodegradable (OBP)

- Soft touch

- Paper feel

- UV inhibitor & blockers

- Security tracers

- Fillers

- Decorative additives

- Post consumer/industrial

- UV brightener

.jpg)

- 0.95 mil (0.00095") to 40.0 mil (0.04")

- Finished roll width: 1” to 80”

(Note: slit widths down to ¼” are possible depending on the film type)

.jpg)

Corona treatment is available to aid printing, laminating and tape adhesion.

Complete Project Management

For more information, please download our capabilities summary sheet.

For needs including printing, laminating, bag converting, die cutting or sheeting, Film Tech LLC can coordinate any or all of these subsequent converting needs to insure the end use need is fulfilled.

Our expertise allows us to use our capabilities in a creative manner, offering custom features for unique product development. Ask Us how we can help you – explain the end result you desire and we will quickly determine options that may be feasible.

.jpeg)

.jpg)

.jpg)